Kategoriler

Yeni blog

Endüstriyel gaz sensörleri nasıl seçilir?

January 13 , 2026Endüstriyel ortamlarda gaz sensörleri, güvenlik ve çevre koruma için "ilk savunma hattı" görevi görür. Özellikle hidrojen sülfür tespiti senaryolarında profesyonel ekipman vazgeçilmezdir. Elektrokimyasal algılama teknolojisine dayalı endüstriyel sınıf bir cihaz olarak, RS485 hidrojen sülfür vericisi Bu, birçok saha uygulaması için standart bir konfigürasyon haline gelmiştir. Doğru sensör tipinin seçimi, tehlike uyarılarının güvenilirliğini, mevzuata uyumu ve üretim istikrarını doğrudan belirler. Karmaşık seçim gereksinimleri için, aşağıdaki temel yönergeler işletmelerin doğru kararlar almasına yardımcı olabilir.

Zorlu çalışma koşullarında, çevresel uyum yeteneği sensörlerin kullanım ömrünü ve ölçüm doğruluğunu doğrudan etkiler. RS485 hidrojen sülfür transmitteri, -20°C ila 60°C sıcaklık aralığında istikrarlı çalışma sağlayarak olağanüstü performans sunar. Aynı anda -40°C ila +80°C arasındaki ortam sıcaklıklarını ve %0 ila %99,9 bağıl nem seviyelerini izleyebilir, bu da onu çoğu endüstriyel senaryo için uygun hale getirir.

Temel performans, tepki süresi, doğruluk ve kararlılığa odaklanmalıdır. Hidrojen sülfür erken uyarısı için, RS485 hidrojen sülfür vericisi gibi hızlı tepki veren elektrokimyasal cihazlar tercih edilen seçenektir. Mevzuat uyumluluğu izleme için, yüksek hassasiyetli 0~50 ppm çıkışı güvenilirdir; daha yüksek hassasiyet gereksinimleri için ise ppb seviyesinde lazer sensörler seçilebilir.

Maliyet değerlendirmelerinde sadece satın alma fiyatı değil, tüm yaşam döngüsü dikkate alınmalıdır. RS485 hidrojen sülfür transmitteri, geniş 5~28VDC voltaj beslemesi ve 0,6 kg'lık hafif tasarımı sayesinde düşük kurulum ve aksesuar maliyetlerine sahiptir. İlk satın alma fiyatı yarı iletken sensörlerden daha yüksek olsa da, daha uzun hizmet ömrü ve daha düşük bakım ihtiyaçları sunarak uzun vadede daha yüksek maliyet etkinliği sağlar.

Yarı iletken sensörlerin birim fiyatı düşüktür ancak sık sık değiştirilmeleri gerekir. Buna karşılık, kızılötesi sensörler yüksek başlangıç maliyetine sahip olsa da güçlü kararlılık ve düşük kalibrasyon sıklığı sunar.

Endüstriyel karışık gaz ortamlarında sensör seçiciliği kritik öneme sahiptir. Yarı iletken sensörler, sıcaklık ve nem girişimini azaltmak için yerleşik dengeleme algoritmalarıyla entegre edilmelidir; katalitik yanma sensörleri ise silisit "zehirlenmesini" önlemek için sinterlenmiş metal filtrelerle donatılmalıdır.

Bakım açısından, basit kalibrasyon ve kendi kendine teşhis fonksiyonlarına sahip modellere öncelik verilmelidir: elektrokimyasal sensörler altı ayda bir kalibrasyon gerektirirken, kızılötesi sensörlerin kullanım ömrü 5-10 yıldır ve bu da bakım maliyetlerini önemli ölçüde azaltabilir.

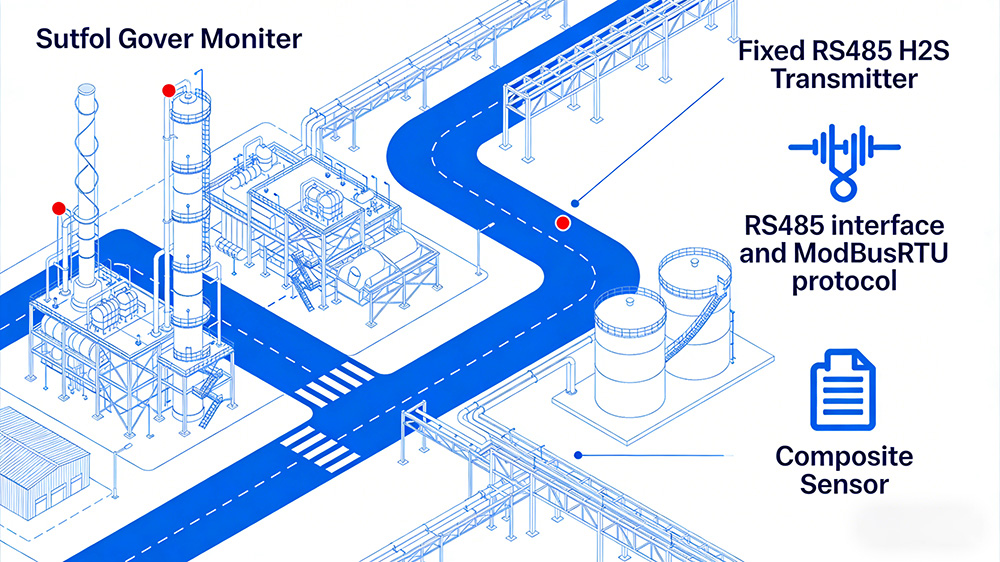

Zehirli ve yanıcı gazların bir arada bulunduğu petrokimya tesisleri için "nokta-yüzey kombinasyonu" stratejisi önerilir: potansiyel H₂S sızıntı noktalarının yakınına sabit RS485 hidrojen sülfür vericileri (RS485 arayüzü ve ModBus RTU protokolü ile donatılmış olup, merkezi veri yönetimini destekler ve uzaktan izlemeyi kolaylaştırır) kurun ve kanal alanlarına kompozit sensörler yerleştirin.

Hidrojen sülfürün birikme eğiliminde olduğu atıksu arıtma tesisi kuyuları gibi kapalı alanlar için, giriş öncesi test amacıyla taşınabilir hidrojen sülfür dedektörleri sağlanmalıdır. Bu arada, gerçek zamanlı izleme sağlamak için bu kapalı alanların etrafındaki önemli izleme bölgelerine sabit RS485 hidrojen sülfür vericileri kurulmalıdır.

Endüstriyel gaz sensörlerinin seçimi, hedef uyumluluğu, çevresel uyum, performans uyumluluğu ve maliyet kontrolü arasında bir denge kurma sürecidir. Temel gereksinimleri netleştirerek, kilit performans göstergelerine odaklanarak ve senaryoya özgü deneyimlerden yararlanarak, işletmeler endüstriyel tesisleri için gerçekten uygun sensörleri seçebilir ve böylece üretim ve operasyonlar için sağlam bir güvenlik bariyeri oluşturabilirler.

Daha fazla bilgi için lütfen web sitemizi ziyaret edin: https://www.zonewuiot.com/gas-sensors_c11